Contrib:Claws/Real world study CodeSaturne

Contents

Real world study with Code Saturne

Content

Introduction

For a long time I've wanted to try and use CFD for a practical purpose and compare it to real-world results, and now during my internship, I have the chance to try it out. For all intent and purposes, I'm far from an expert on CFD nor fluid dynamics, but I have done a few experiments and have a good general idea of how things come together in fluid dynamics/CFD. What this sums up to, is 'nothing is written in stone here' – There may be errors and the setup is probably far from optimal, there is always room for improvement.

- Here is a hands on case with Code Saturne without getting too technical.

Scenario

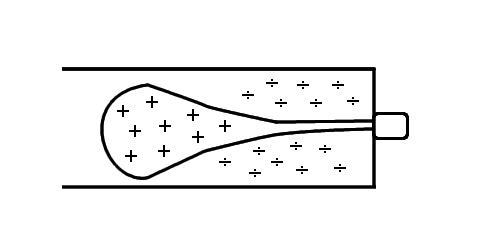

In a gas fire a burner tube is used to mix the fuel (in this case natural gas) with oxygen using the Venturi effect. The pressurized fuel is sent from the high pressure bottle, through a regulator and from the regulator through a nozzle into the burner tube. The gas jet from the nozzle creates a low pressure zone around the base of the jet which sucks in air through the aeration port and mixes it in the burner tube before it is sent into the burner1.

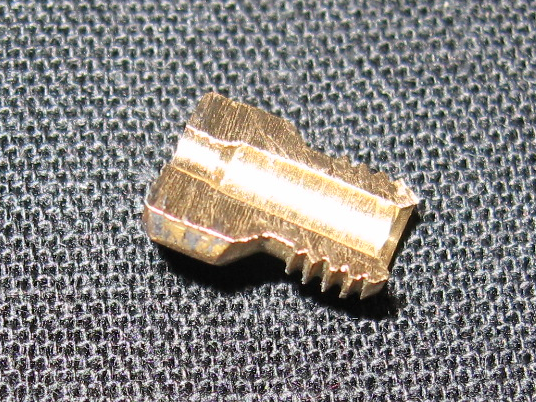

Among other things, the geometry of the nozzle and the velocity of the fluid determines the shape of the jet and the magnitude of the low pressure zone. In this case I've guestimated a discharge coefficient of 0.5, based on the geometry of the nozzle and calculated the exit velocity accordingly.

The exit orifice has a diameter of ~1.9mm

In this study I wont simulate what happens inside the nozzle, nor will I concern myself too much whether the shape of the gas jet is physically correct at the exit – That will be discussed a bit more later on.

Mathematical approach

Collecting data

For my simulation I need to input some data into the model, this was done in the following manner:

- Measure volumetric flow rate of the gas going into the burner tube using a flow-meter on the actual gas fire and compare it to the technical documents specified by the test lab

- Guestimate a discharge coefficient for the nozzle using empirical numbers from a table

- Acquiring physical properties for natural gas (using pure methane)

- Measure pressure differential on the regulator

- Calculate exit velocity of gas jet using above values

Calculating the exit velocity at the nozzle has been done in two ways – using the flow rate and using a theoretical approach. Both results equals ~38m/s but since I know that that is a bit high considering the setup and the values used, I back it down a bit to ~33m/s for the simulation.

See Media:Mathcad-dyse.xmcd.pdf MathCAD PDF for calculation.

Simulation approach

Software

- SolidWorks for modeling the flow domain

- Salomé 4.1.4 for preparing geometry and meshing flow domain

- Code Saturne 1.4b for solving the simulation

- Paraview 3.4.0 for Post processing

Everything besides SolidWorks is run on Ubuntu 8.10 Linux – SolidWorks could easily be replaced by Salomé but laziness dictated I did it in SW at work.

The computer used is my trusty Zepto Znote 6014W, 1.7ghz Celeron, 1GB RAM

Model description and preparation

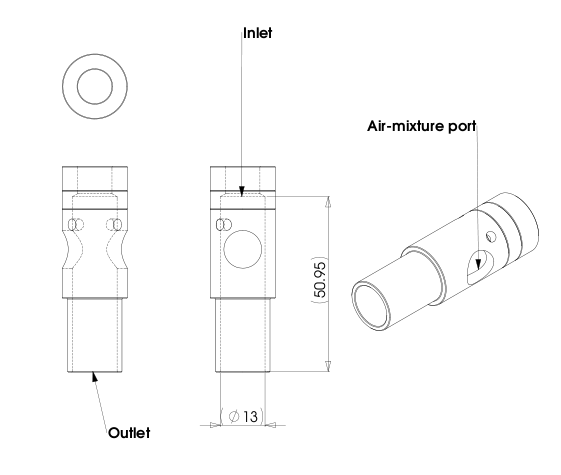

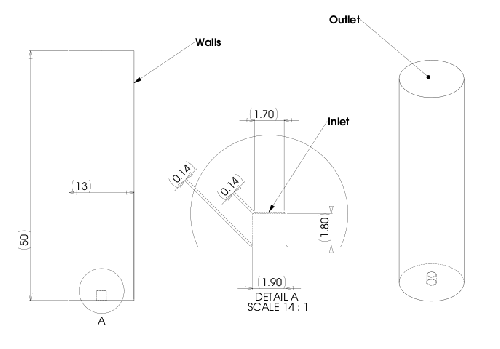

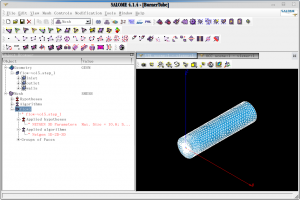

The simplified flow domain consists of a cylinder (Ø13mm, h 50mm) with a simplified inlet (remember, I don't care too much about what happens near and around the inlet).

This is exported from SolidWorks in STEP file format and assigned groups in Salomé geometry module, before it is meshed in the meshing module using the following parameters:

- NetGen 1D-2D-3D using the setting 'very fine' and 'quadratic' (2nd order) – the NetGen algorithm and geometry makes sure that the mesh is refined around the inlet and coarsens further up the flow domain.

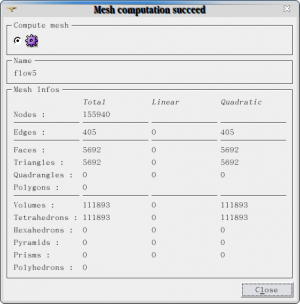

This yields the following mesh:

Again, without getting too technical, a way to make sure your mesh is optimized for the simulation, you can calculate the Courant number and adjust your mesh accordingly. ((u*deltat)/deltax)<C

Preparing and running simulation

The mesh is exported in MED file format to the folder ~/Study/MESH/ and the Saturne GUI is started from ~/Study/CASE1/DATA/ using ./SaturneGUI

Code Saturne GUI

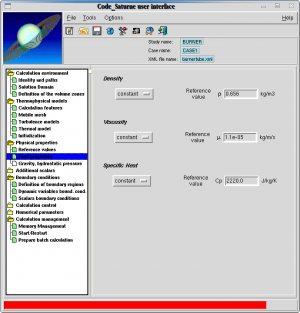

Once the GUI has loaded, it is time to enter the values (the options/tabs not mentioned is left at default if nothing is stated).

Under Solution domain load the mesh file exported from Salomé :

Next go into Thermophysical models and set the turbulence model to k-epsilon – This is a high Renolds number model since that's what I have here.

Initialization is set as seen here:

Next the physical properties of the fluid needs to be set:

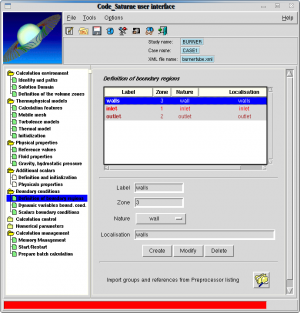

Definition of boundary regions are set next – the names of the boundary regions corresponds to the group names assigned in Salomé.

Entering the calculated velocity in the positive Y-direction in Dynamic variables bound. cond.

Since this is a steady state condition, this is what I left it at in Steady Management.

Under Output control I set it to Post-processing every 'n' time step to 1 and select Ensight Gold as the output format (This is so ParaView can post-process the result):

Once everything is set up, theres only one thing left: Load the 'runcase' file under Prepare batch calculation and press Code Saturne batch running:

This launches the calculation and outputs the temporary results in ~/tmp_saturne and the finished results in ~/Study/CASE1/RESU

As the calculation runs, issueing the terminal command

tail -qf ~/tmp_saturne/Study.CASE1.date/listing

will give info on the progress and convergence of the calculation:

INSTANT 0.220000000E+03 TIME STEP NUMBER 220

=============================================================

** BOUNDARY MASS FLOW INFORMATION

------------------------------

Phase : 1

---------------------------------------------------------------

Boundary type Code Nb faces Mass flow

---------------------------------------------------------------

Entree 2 349 -0.489401493E+02

Paroi lisse 5 5207 0.429746002E-16

Paroi rugueuse 6 0 0.000000000E+00

Symetrie 4 0 0.000000000E+00

Sortie libre 3 136 0.489401492E+02

Indefini 1 0 0.000000000E+00

---------------------------------------------------------------

** BOUNDARY CONDITIONS FOR SMOOTH WALLS

---------------------------------------

------------------------------------------------------------

Phase 1 Minimum Maximum

------------------------------------------------------------

Rel velocity at the wall uiptn : -0.27173E+01 0.84489E+01

Friction velocity uet : 0.37369E-03 0.43771E+00

Friction velocity uk : 0.54475E-01 0.41828E+01

Dimensionless distance yplus : 0.50161E+02 0.40720E+05

------------------------------------------------------

Nb of reversal of the velocity at the wall : 1

Nb of faces within the viscous sub-layer : 0

Total number of wall faces : 5207

------------------------------------------------------------

Phase 1 incoming flow detained for 31 outlet faces on 136

** INFORMATIONS ON THE CONVERGENCE

-------------------------------

---------------------------------------------------------------

Variable Rhs norm N_iter Norm. residual derive

---------------------------------------------------------------

c Pressure 0.78903E+01 916 0.97950E-08 0.40786E+00

c VelocitU 0.71071E+02 134 0.92046E-08 0.94592E-01

c VelocitV 0.67696E+03 116 0.89371E-08 0.59835E+00

c VelocitW 0.73505E+02 126 0.95992E-08 0.71705E-01

c TurbEner 0.76674E+03 98 0.97515E-08 0.26028E+00

c Dissip 0.58401E+06 42 0.95251E-08 0.32006E+03

---------------------------------------------------------------

** INFORMATIONS ON THE VARIABLES

-----------------------------

---------------------------------------------------------------

Variable Min. value Max. value Min clip Max clip

---------------------------------------------------------------

v Pressure -0.63469E+02 0.28898E+02 -- --

v VelocitU -0.69839E+01 0.82191E+01 -- --

v VelocitV -0.13238E+02 0.37839E+02 -- --

v VelocitW -0.76948E+01 0.82500E+01 -- --

v TurbEner 0.55144E-03 0.87445E+02 0 0

v Dissip 0.63614E-02 0.36588E+05 8 0

v turb. vi 0.53370E-06 0.13664E+01 0 0

v total_pressu 0.10124E+06 0.10133E+06 0 0

---------------------------------------------------------------

** INFORMATIONS ON THE CLIPPINGS

-----------------------------

---------------------------------------------------------------

Variable Min wo clips Max wo clips Min clip Max clip

---------------------------------------------------------------

a TurbEner 0.55144E-03 0.87445E+02 0 0

a Dissip -0.87143E+02 0.36588E+05 8 0

---------------------------------------------------------------

CPU TIME FOR THE TIME STEP 220: 0.43967E+02

***************************************************************

If everything went smoothly, Code_Saturne rewards you with a “Normal Simulation Finished” and one can move on to...

Post processing

Fire up ParaView and select File → open → Study/CASE1/RESU/CHR.ENSIGHT.date/chr.case

Click 'apply' and select Filters → Alphabetical → Cell data to point data and Filters → Common → Slice and de-select show plane select Z Normal – click apply

Cell data to point data will give a much more smooth representation of the fields and allow showing the velocity field as streamlines.

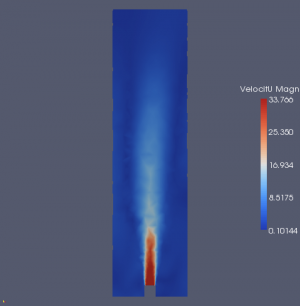

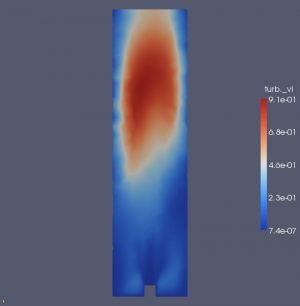

Images are captured at timestep 200 where we have a reasonably steady state:

Pressure:

Velocity:

Turbulent energy:

Turbulence – magnitude

ParaView set up with Plot over line to show values along the X axis:

[[Image:|thumb|Illustration 17: Plot over line]]

So after post processing the simulation, what conclusions can be drawn?

Velocity is indeed 33m/s as was the initial condition.